Assist to get small-scale nuclear fusion off the ground !

Support promising route to a new form of sustainable energy

Participation possible with just 100 euros - you become a co-owner

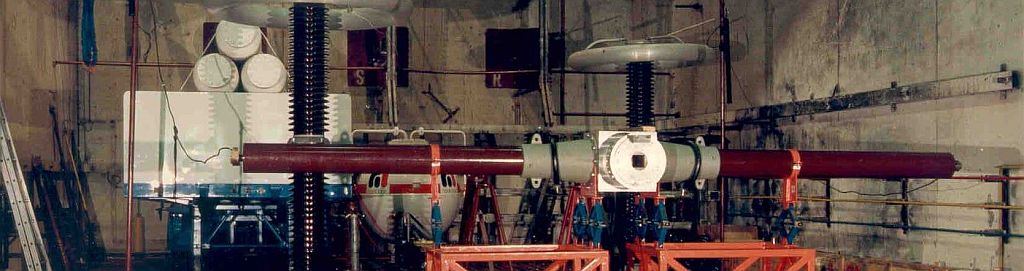

Convectron experiments at KEMA High Power Laboratory, Arnhem, The Netherlands, 1987

The Convectron nuclear fusion reactor: ignition, reactor and fuel injection

Atmospheric fusion regime

Moist air contains fuel for nuclear fusion at the level of a Tokamak reactor. On three thousand normal molecules, water has one heavier molecule with hydrogen replaced by deuterium. Thus water vapour endows air with fusion fuel at levels that match the stratospheric rarefaction of Tokamak plasma's.

Lightning discharges change a gas of neutral molecules into a plasma mixing atoms, ions and free electrons. Lightning plasmas emit radiation with more energy than deuterium needs for fusion. Atmospheric neutrons also connect lightning with fusion of deuterium nuclei. Steady deuterium fusion enhances lifetimes in the Convectron model of high-energy ball lightning.

Inside the Convectron fireball, space charge of plasma vortices creates a central force field. A boson condensate circulates at speeds causing fusion reactions of co-rotating deuterium nuclei. The fusion process shoots tritons and helium-3 in all directions. Coloured halo's on the outside bear witness to interior fusion activity.

Wire-based electrode

For ignition of fusion Convectron's predecessor fitted a supersonic nozzle with electrodes for high-voltage breakdown. The photo on the top of the page shows this Laval nozzle face-on as installed in KEMA's test bunker. With dielectric mouthpiece the same facility in KEMA's Syntheticahal withstood deuterium injection and neutron counts in the concluding test series.

Since then Convectron heard privately about erosion-free fireball formation by early laser tests. Its high-voltage circuit accidentally induced fireballs from a coil. Emerging technologies using microwave photonics guide Convectron's wire-based electrode design. Extensive protection by patents is core business in planned R&D activities.

Flow pattern in reactor vessel

Convectron's predecessor held patents on reactor vessel design with two polar inlet nozzles and an equatorial outlet torus as drawn on the left. Gas flow drags fireballs away from discharge space into the reactor vessel. Fireballs find and retain their stable position in a tunable flow pattern.

A demonstration model readily keeps styrofoam spheres floating freely on a gas jet flowing from the narrow tube inside the vessel.

Flow dynamics as described above controls fireball position in Convectron's reactor vessel design. Basic patents on the point source and ring sink pattern have lapsed, but new calculus of gas dynamics holds promise for new patents on best wall contour and nozzle design.

Fuel injection for output control

Convectron's concluding test series in KEMA's Syntheticahal released compressed nitrogen gas for expansion as transonic flow past copper electrodes. On the way to the discharge nozzle a mixing unit injected deuterium as fusion fuel into the inert carrier gas. Turbulent mixing in a long entrance duct enhanced diffusion of deuterium into nitrogen for uniform gas composition. The complete facility combines mixing unit, electrode section, reactor vessel and waste removal flushed by gas circulation near atmospheric pressure. Cryogenic technology for liquid air freezes out waste products including helium gas with rest value for welding. Injection and removal units control reaction rates via fuel concentration as in combustion engines. Scale rules for deuterium-rich fuel easily raise fireball fusion output from natural to commercial power levels.

Support this favourable and promising initiative and join in!

Buy a share ...

... for only 100 euros

© 2012-2019 Convectron Natural Fusion N.V. - Rotterdam / Utrecht - The Netherlands

Convectron in the social media